Material Specification

| DET | QTY | Name | Material |

|---|---|---|---|

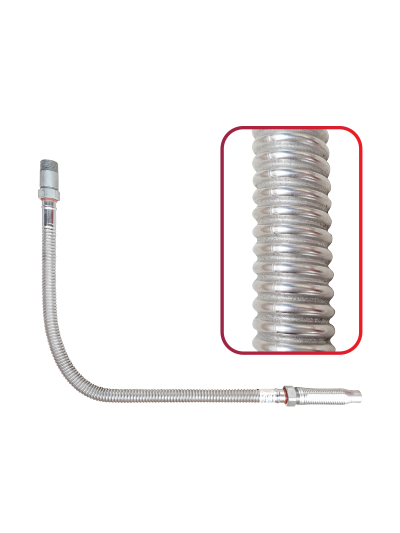

| 1 | 1 | Corrugated Tube | AISI 304 Stainless Steel |

| 2 | 2 | Sealing O-Ring | EPDM |

| 3 | 2 | Isolation Ring | Nylon 66 |

| 4 | 2 | Slip Nut | Carbon Steel ASTM 1020#, Zinc-plated |

| 5 | 1 | Discharge Nipples | Carbon Steel ASTM 1020#, Zinc-plated |

| 6 | 1 | Inlet Nipples | Carbon Steel ASTM 1020#, Zinc-plated |

| 7 | 1 | Center Brackets | Carbon Steel ASTM A283M, Zinc-plated |

| 8 | 2 | Side Brackets | Carbon Steel ASTM A283M, Zinc-plated |

| 9 | 1 | Square Bar | Carbon Steel ASTM A283M, Zinc-plated |

| 10 | 1 Set | Hexagon Screws (Options for wing screws) |

Carbon Steel ASTM A283M, Zinc-plated |

Notes

UL&ULC Listed

TECHNICAL DATA

Working pressure : 200psi

Burst pressure : 875psi

Maximum Ambient Temperature: 150°F / 66°C

Connection: DN25 x DN15 (1″ x ½”) / DN25 x DN20 (1″ x ¾”), NPT or BSPT

Hose Diameter: O.D. 26.8mm (1-1/16″), Flow diameter 22.5mm (7/8″)

| Assembling Length

mm inch |

In-&Outlet Head Size

DN in. |

Max.number of 90° bends

n x 90″ |

Min bending radius

mm inch |

Equivalent Length of DN25/1″ Sch. 40 Pipe at C=120 in QF-600 With straight discharge Nipple* |

|---|---|---|---|---|

| 700 28 |

25 x 15 1″ x 1/2″ |

1 | 100 4 |

5.5 18 |

| 1000 40 |

25 x 15 1″ x 1/2″ |

2 | 100 4 |

10 33 |

| 1200 48 |

25 x 15 1″ x 1/2″ |

2 | 100 4 |

13 43 |

| 1500 60 |

25 x 15 1″ x 1/2″ |

3 | 100 4 |

19.2 63 |

| 1800 72 |

25 x 15 1″ x 1/2″ |

4 | 100 4 |

23.8 78 |

| 700 28 |

25 x 20 1″ x 3/4″ |

1 | 100 4 |

7.3 24 |

| 1000 40 |

25 x 20 1″ x 3/4″ |

2 | 100 4 |

12.5 41 |

| 1200 48 |

25 x 20 1″ x 3/4″ |

2 | 100 4 |

14 46 |

| 1500 60 |

25 x 20 1″ x 3/4″ |

3 | 100 4 |

19.5 64 |

| 1800 72 |

25 x 20 1″ x 3/4″ |

4 | 100 4 |

24.4 80 |

Results are tested & recorded by UL under minimum bending radius in maximum bending degrees.

Results are tested & recorded by FM approvals under minimum bending radius in maximum bending degrees.

ASSEMBLY INSTRUCTIONS

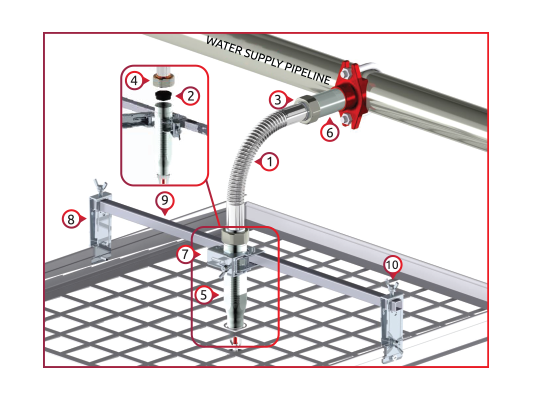

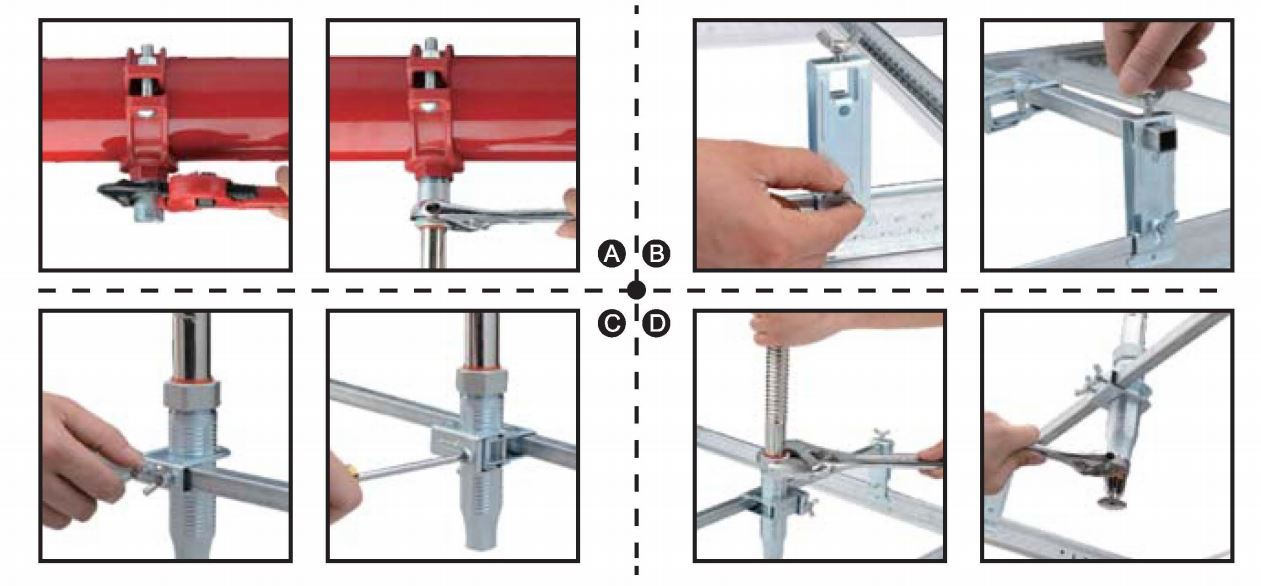

A. Connect Inlet Nipple

Use pipe wrench to screw the Inlet Nipple into the branch outlet interface on water supply pipeline, use pipe sealant (Teflon tape or pipe glue etc.) to seal and apply tightening torque of approx. 5ON·m/35ft-lbs. Then tighten the Hexagon Slip Nut with 15N·m/10ft-lbs to ensure sealing performance.

B. Fix bracket set

Attach side brackets to the main-rail of the T-bar grid and cross the square bar through 2 side brackets, with the center bracket in the middle. Tighten all fixing bolt on the side brackets with 4N·m/3ft-lbs.

C. Bending & Locating

Bend the Flexible Hose body as desired (According the parameters on Specification sheet) and locate the Discharge Nipple into the center bracket. Tighten the bolts on center bracket with 4N·m/3ft-lbs after the proper location of spring kier head has been found.

D. Connect Discharge Nipple

Tighten the Slip Nuts with 15N·m/10 ft-lbs and install sprinkler head to Discharge Nipple by following the sprinkler manufacture’s installation instructions. Finally test leak in according with NFPA guidelines.

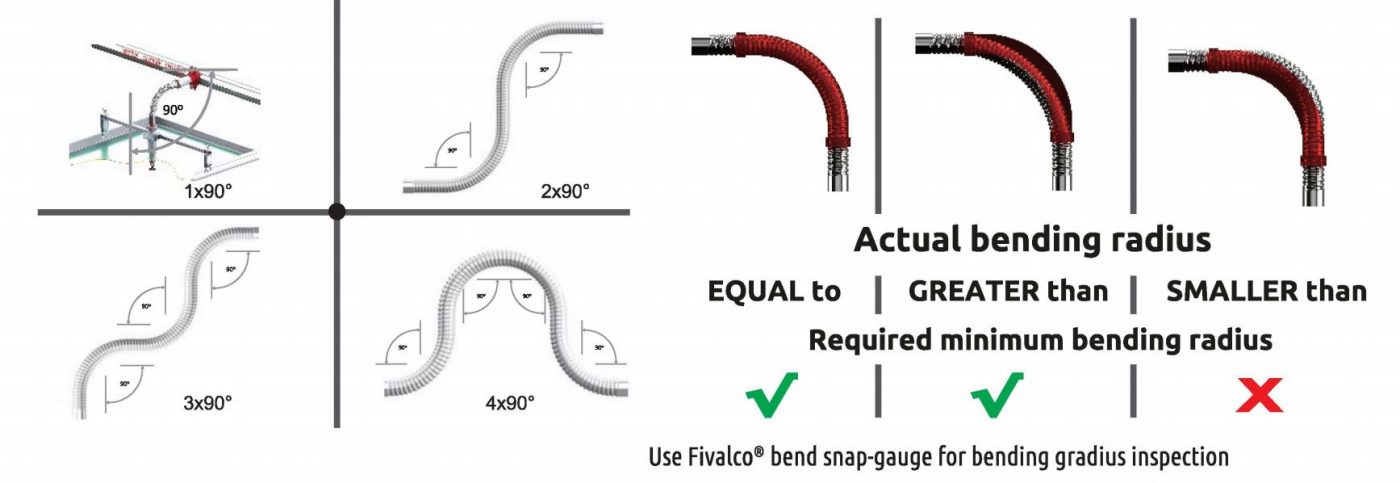

HOSE BENDING, CORRECT OR WRONG?

cALCULATION OF BENDING DEGREES

| Cartoon box | Pallet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Qty | Gross weight | Size | Quantity | Gross weight | ||||||||

| Hose Length | L | W | H | QF-600 | QF-1000 | L | W | H | Box | Hose | QF-600 | QF-1000 | |

| mm | mm | mm | mm | ea | kg | kg | mm | mm | mm | ea | ea | kg | kg |

| 700 | 1050 | 205 | 195 | 20 | 27.2 | 31.5 | 1050 | 1050 | 1125 | 25 | 500 | 700 | 805 |

| 1000 | 1300 | 205 | 195 | 20 | 28.9 | 35.3 | 1300 | 1050 | 1125 | 25 | 500 | 745 | 905 |

| 1200 | 1500 | 205 | 195 | 20 | 30.2 | 37.7 | 1500 | 1050 | 1125 | 25 | 500 | 780 | 970 |

| 1500 | 1800 | 205 | 195 | 20 | 32 | 42 | 1800 | 1050 | 1125 | 25 | 500 | 830 | 1080 |

| 1800 | 2100 | 205 | 195 | 20 | 34 | 45.6 | 2100 | 1050 | 1125 | 25 | 500 | 885 | 1175 |