TECHNICAL SPECIFICATIONS

| Size | DN40 … DN700 |

| Body Design | Lugged |

| Working Pressure | 16bar |

| Shell Testing Pressure (x1.5) | 24bar |

| Seat Testing Pressure (x1.1) | 17.6bar |

| Working Temperature | -20°C…110°C (EPDM Seat) -10°C…80°C (NBR Seat) 5°C…120°C (PTFE Seat) -10°C…135°C (FPM Seat) |

| Applicable Medium | Water, Oil, Gas |

| Operator | Lever, Wormgear, Electric Actuator |

| Connection | BS 4505 PN10 / PN16, EN1092-2 PN10 / PN16, JIS B2239 10K / 16K, ANSI Class 125 / 150 |

| Optional Accessories | Chain Wheel, Limit Switch |

Material Specification

| Part | Material |

| Body | Ductile Iron Stainless Steel 304 Stainless Steel 316 |

| Disc | Ductile Iron Aluminium Bronze Stainless Steel 304 Stainless Steel 316 |

| Seat | EPDM / NBR / PTFE (Teflon) / FPM (Viton) |

| Part | Material |

| Stem | Stainless Steel 410 Stainless Steel 431 Stainless Steel 316 |

| Taper Pin | Stainless Steel 316 / Stainless Steel 410 |

| O-Ring | EPDM / NBR / FPM (Viton) |

| Bushing | PTFE |

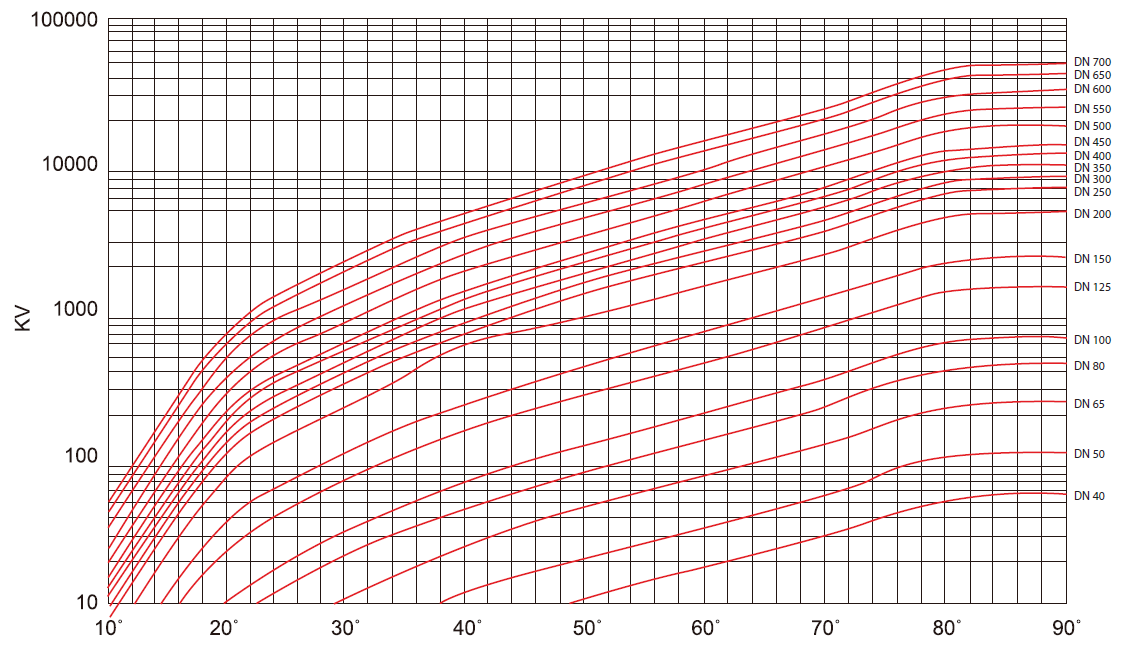

VALVE COEFFICIENT

| DN | (mm)

(inch) |

40

1 1/2 |

50

2 |

65

2 1/2 |

80

3 |

100

4 |

125

5 |

150

6 |

200

8 |

250

10 |

300 12 |

| Cv | 69 | 135 | 220 | 302 | 600 | 1022 | 1579 | 3136 | 5340 | 8250 |

| DN | (mm)

(inch) |

350

14 |

400

16 |

450

18 |

500

20 |

550

20 |

600

24 |

650

26 |

1200 48 |

| CV | 11917 | 16388 | 21705 | 27908 | 35170 | 43116 | 45620 | 49500 |

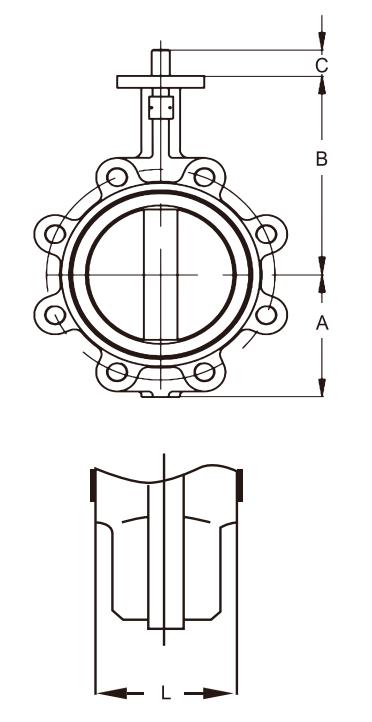

DIMENSIONS VALVE BODY

| DN | (mm)

(inch) |

40

1½ |

50

2 |

65

2½ |

80

3 |

100

4 |

125

5 |

150

6 |

200

8 |

250

10 |

| A | 66 | 68.6 | 76 | 99 | 119 | 129 | 142 | 176 | 209 | |

| B | 130 | 141.2 | 150.4 | 156.5 | 168 | 186.5 | 205.7 | 230.6 | 269.9 | |

| C | 15 | 15 | 19 | 19 | 19 | 19 | 19 | 25 | 32 | |

| L | 33 | 42 | 45 | 45 | 51 | 55 | 55 | 60 | 67 |

| DN | (mm)

(inch) |

300

12 |

350

14 |

400

16 |

450

18 |

500

20 |

550

22 |

600

24 |

650

26 |

700

28 |

| A | 248.5 | 267 | 309 | 327 | 389 | 433 | 453 | 484 | 530 | |

| B | 327.8 | 368 | 400 | 422 | 480 | 533 | 562 | 540 | 626 | |

| C | 32 | 40 | 52 | 52 | 64 | 70 | 70 | 70 | 95 | |

| L | 76 | 76 | 102 | 114 | 127 | 151 | 151 | 172 | 165 |

Note: DN650 only available in ANSI Class 150 Flange.

DIMENSIONS - VALVE OPERATOR

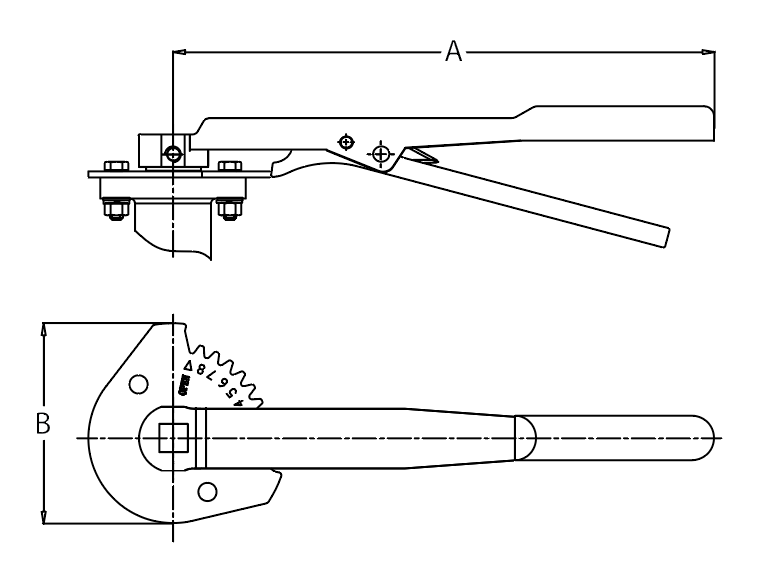

Malleable Iron / Stainless Steel Lever.

Stainless Steel 304 Top Indicator Plate.

| DN | (mm)

(inch) |

40-80

1.5-3 |

100-125

4-5 |

150

6 |

200-250

8-10 |

300

12 |

| A | 195 | 266 | 328 | 386 | 391 | |

| B | 95 | 109 | 109 | 164 | 164 |

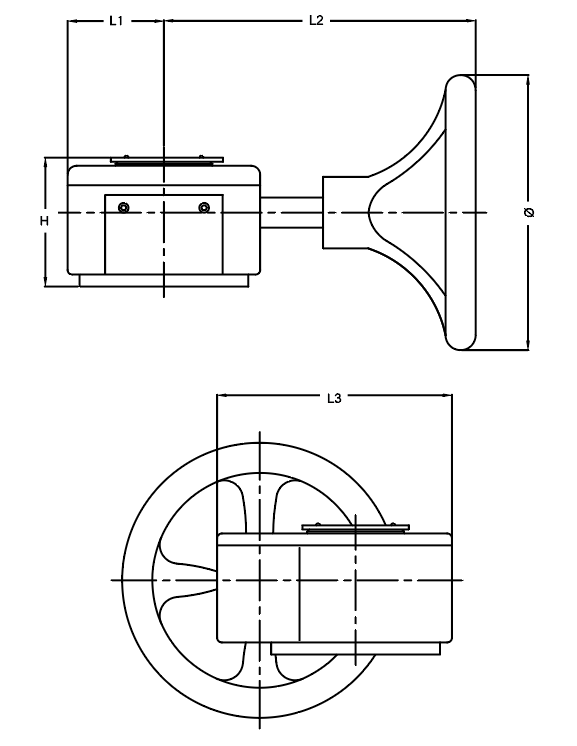

| Cast Iron 1 – Stage Worm Gear and Handwheel |

| Carbon Steel Gear Box Shaft |

| Valve Diameter | H | ø | L1 | L2 | L3 |

| DN40…DN150 | 70 | 150 | 52 | 118 | 129 |

| DN200…DN250 | 80 | 280 | 75 | 191 | 171 |

| DN300…DN350 | 80 | 280 | 80 | 186 | 198 |

| DN400…DN450 | 99 | 400 | 125 | 273 | 280 |

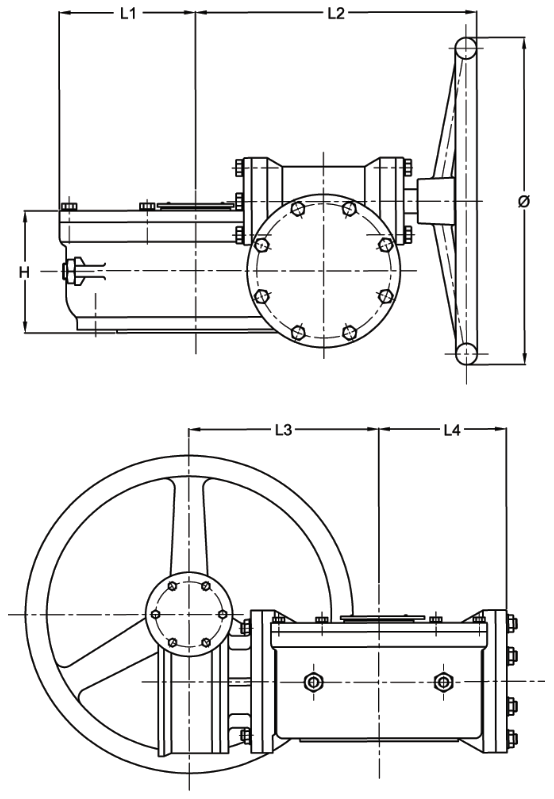

| Cast Iron 2 – Stage Worm Gear and Handwheel |

| Carbon Steel Gear Box Shaft |

| Valve Diameter | H | ø | L1 | L2 | L3 | L4 |

| DN400…DN500 | 125 | 285 | 107 | 260 | 175 | 107 |

| DN600 | 136 | 385 | 131 | 285 | 193 | 131 |

| DN700…DN800 | 158 | 425 | 173 | 359 | 245 | 173 |

| DN900…DN1100 | 185 | 425 | 201 | 399 | 279 | 201 |

| DN1200 | 216 | 425 | 185 | 443 | 311 | 255 |