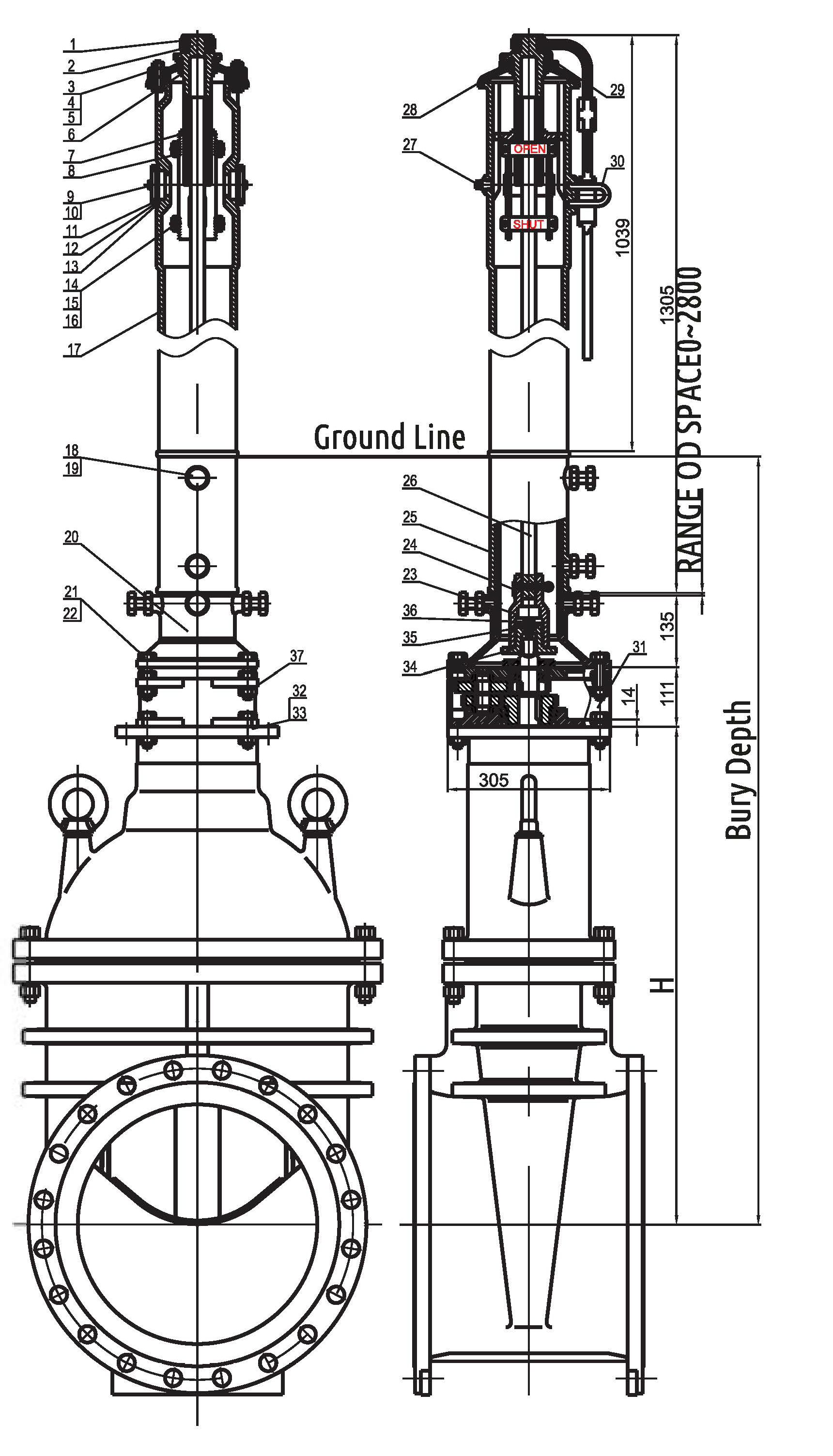

Material Specification

| No. | Name | Material |

|---|---|---|

| 1 | Locking Wrench | ASTM A536 |

| 2 | Operating Nut | ASTM B62/A351 CF8 |

| 3 | Bolt | ASTM A105 |

| 4 | Nut | ASTM A105 |

| 5 | Flat Washer | ASTM A105 |

| 6 | Shap Ring | AISI 606 |

| 7 | Taget Carrier Nut | ASTM B62 |

| 8 | Target | ASTM B108 |

| 9 | Bolt | ASTM A105 |

| 10 | Flat Washer | ASTM A105 |

| 11 | Window Gland | ASTM A307B |

| 12 | Window Glass | LEXAN-UN STABILIZE |

| 13 | Gasket | EPDM |

| 14 | Bolt | ASTM A105 |

| 15 | Spring Washer | ASTM A105 |

| 16 | Nut | ASTM A105 |

| 17 | Body | ASTM A105 |

| 18 | Bolt | ASTM A105 |

| 19 | Nut | ASTM A105 |

| 20 | Base Flange | ASTM A126B |

| 21 | Bolt | ASTM A105 |

| 22 | Nut | ASTM A105 |

| 23 | Crane Coupling | ASTM A536 |

| 24 | Cotter Pin | AISI 304 |

| 25 | Stand Pin | ASTM A536 |

| 26 | Stem 1″ Square | AISI 1045 |

| 27 | Plug | AISI 304 |

| 28 | Top Cover | ASTM A126B |

| 29 | Screw | AISI 304 |

| 30 | Lock Nose | ASTM A307B |

| 31 | Reducer | PARTS |

| 32 | Bolt | ASTM A105 |

| 33 | Nut | ASTM A105 |

| 34 | Wrench Nut | ASTM A536 |

| 35 | Washer | AISI 304 |

| 36 | Hex, Socket Cap Screw |

AISI 304 |

| 37 | Spring Washer | AISI 304 |

BURY DEPTH

| Valve Size | Min. Bury Depth (inch) |

Max. Bury Depth (inch) |

H1 | H2 | ||

|---|---|---|---|---|---|---|

| mm | inch | mm | inch | |||

| 14″ | 50.87″ | 158.35″ | 741 | 29.17″ | 889.5 | 35.02″ |

| 16″ | 53.82″ | 161.30″ | 816 | 32.13″ | 964.5 | 37.97″ |

| 18″ | 58.54″ | 166.02″ | 936 | 36.85″ | 1084 | 42.68″ |

| 20″ | 61.89″ | 169.37″ | 1021 | 40.20″ | 1169 | 46.02″ |

| 24″ | 67.87 | 175.35″ | 1173 | 46.18″ | 1344.5 | 52.93″ |

FIELD ADJUSTMENT

1. Remove the top section from the top of the Indicator Post assembly.

2. Cut the required length off the bottom of the Stand pipe for the Gound Line to match up with Standpipe Gound Line mark.

3. Set the “OPEN” and” SHUT” targets for the appropriate valve size.

4. Reattach the Top Section to the top of the Indicator Post assembly.

5. Design and dimensions are subject to change without notice.