BASE FEATURES

The case is processed by means of aluminum die-casting technology and precision machining technique.

Light weight and small size, outer surface is treated through flame plating technique to give an excellent appearance.

Easy to adjust the end position of stoke control and set torque switch and reliable on control.

High accuracy of driving medium, ball bearings are fitted at all rotating positions, high efficiency of whole machine and negligible noise.

Driving of the output shaft is carried out through worm gear and can be self-locked at any position.

There is an mechanical ajustable stop for valve and position control.

The manual/electric declutch is of semi-automation and electric-priority to ensure safe and reliable operation.

Possessing ideal outdoor performance

Various flange connection modes, there is a valve stem adapter in the inner of output shaft, easy to mount and dismount.

Selected Function

4-20mA DC valve position feedback signal

Increasing electric block with automatic adjusting function

Increasing limit switch to give passive control contacts

Performing integral control, possessing local/remote-control shifting function and opening, closing and stop at local control functions

Fitted with heat protection element for electric motor.

Fitted with space heater in the inner of electric control cave.

Turn angle of output shaft is more or less than 90°

Other special function requirement

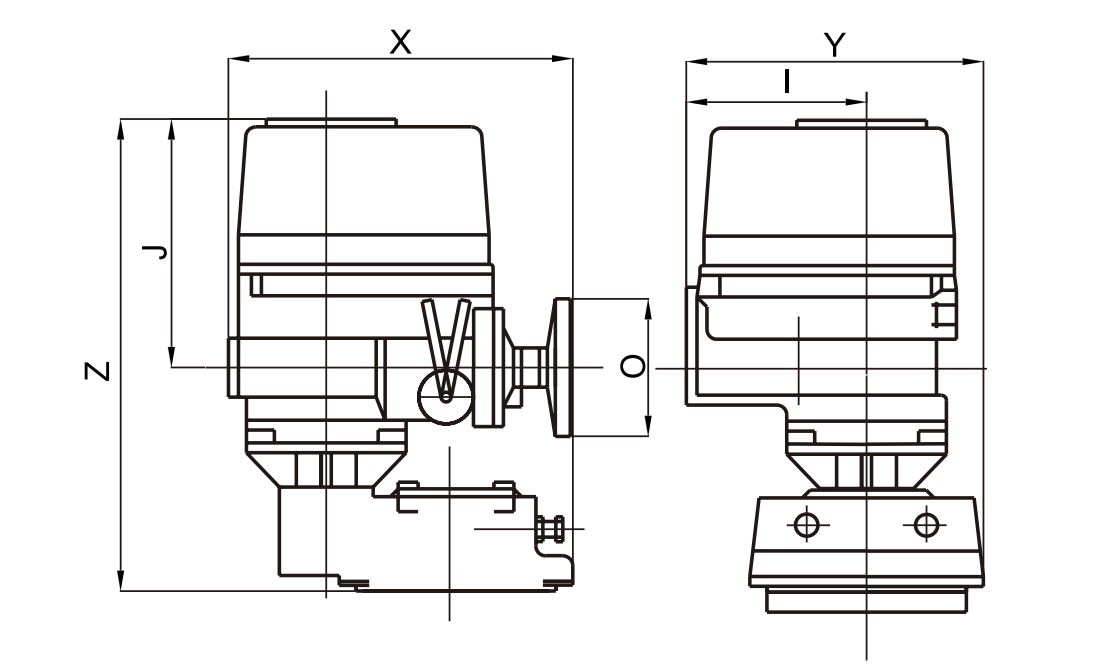

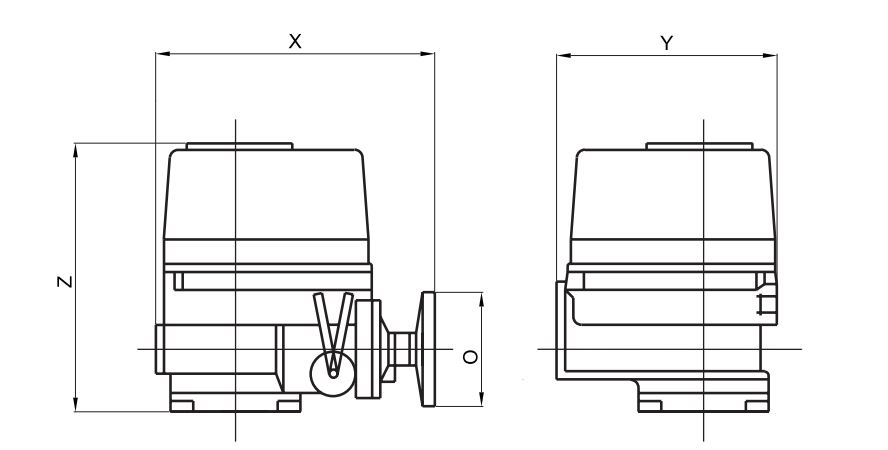

DIMENSIONS(mm)

| Type | QT03 | QT04 | QT06 | QT09 | QT15 | QT19 | QT28 | QT38 | QT50 | QT60 | QT80 | QT100 |

| Flange | F05 | F05 | F07 | F07 | F07 | F07 | F10 | F10 | F10 | F10 F12 |

F05 F12 |

F10 F12 |

| ISO5211 | F07 | F07 | F10 | F10 | F12 | F12 | F12 | F14 | F14 | F14 | ||

| X | 241 | 241 | 241 | 241 | 272 | 272 | 290 | 290 | 290 | 331 | 331 | 331 |

| O | 200 | 200 | 200 | 200 | 250 | 250 | 350 | 350 | 350 | 350 | 350 | 350 |

| Z | 256 | 256 | 256 | 256 | 263 | 263 | 298 | 298 | 298 | 342 | 342 | 342 |

| Y | 208 | 208 | 208 | 208 | 239 | 239 | 274 | 274 | 274 | 306 | 306 | 306 |

| Output Torque(N*m) | 30 | 40 | 60 | 90 | 150 | 190 | 280 | 380 | 500 | 600 | 800 | 1000 |

| Output Speed(r/min) | 0.9 | 0.9 | 0.9 | 0.9 | 0.7 | 0.7 | 0.6 | 0.6 | 0.6 | 0.5 | 0.5 | 0.5 |

| Reference power(kw) | 0.01 | 0.01 | 0.02 | 0.03 | 0.04 | 0.04 | 0.04 | 0.06 | 0.09 | 0.09 | 0.18 | 0.2 |

| Rated current(A) | 0.2 | 0.2 | 0.25 | 0.3 | 0.8 | 0.8 | 0.8 | 1.2 | 1.6 | 1.6 | 3.2 | 3.6 |

DIMENSIONS(mm)

| Type | QT150 | QT200 | QT250 |

| Flange | F16 | F16 | F16 |

| ISO5211 | F14 | F14 | F14 |

| Z | 505 | 505 | 505 |

| J | 264 | 264 | 264 |

| H | 241 | 241 | 241 |

| X | 357 | 357 | 357 |

| O | 350 | 350 | 350 |

| T | 132 | 132 | 132 |

| Y | 323 | 323 | 323 |

| Output Torque(N*m) | 1500 | 2000 | 2500 |

| Output Speed (r/min) | 0.2 | 0.2 | 0.17 |