PRESSURE & TEMPERATURE RATINGS

| Working Pressure | 150 psi |

| Shell Testing Pressure | (x2.0) 300 psi |

| Seat Testing Pressure | (x1.1) 165 psi |

| Working Temperature | -4°F … 230°F (EPDM) 14°F … 176°F (NBR) |

| Suitable Media | Water, Oil & Gas |

Material Specification

| Body | Ductile Iron |

| Disc | Ductile Iron Aluminium Bronze Stainless Steel 304 Stainless Steel 316 |

| Shaft | Stainless Steel 410 Stainless Steel 431 |

| Seat Ring | EPDM/NBR |

| O-Ring | EPDM/NBR |

| Bushing | Bronze |

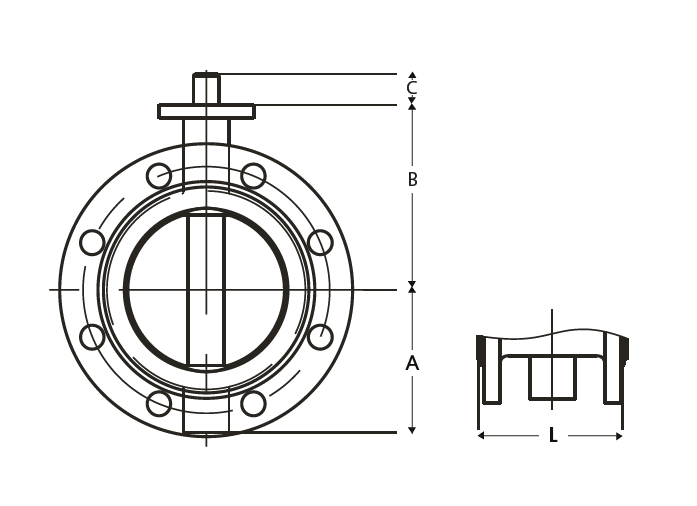

DIMENSIONS

| DN | (mm)

(inch) |

80

3 |

100

4 |

150

6 |

200

8 |

250

10 |

300

12 |

350

14 |

400

16 |

450

18 |

| A | 3.82 | 4.69 | 6.14 | 7.36 | 8.2 | 9.86 | 11.42 | 12.63 | 13.52 | |

| B | 5.16 | 5.91 | 7.09 | 8.27 | 9.67 | 10.83 | 12.91 | 14.8 | 16.01 | |

| C | 1.18 | 1.18 | 1.26 | 1.57 | 1.97 | 1.97 | 1.97 | 2.76 | 3.35 | |

| L | 5 | 5 | 5 | 6 | 8 | 8 | 8 | 8 | 8 |

| DN | (mm)

(inch) |

500

20 |

600

24 |

750

30 |

900

36 |

1050

42 |

1150

46 |

1200

48 |

1350

54 |

1500

60 |

| A | 16.08 | 18.78 | 20.33 | 24.21 | 28.74 | 41.2 | 39.4 | 45.7 | 50.1 | |

| B | 17.64 | 20.39 | 24.02 | 27.24 | 34.06 | 41.8 | 34.8 | 39.2 | 41.8 | |

| C | 3.74 | 4.33 | 3.74 | 5 | 5.12 | 5.91 | 5.91 | 7.87 | 7.87 | |

| L | 8 | 8 | 12 | 12 | 12 | 15 | 15 | 15 | 15 |

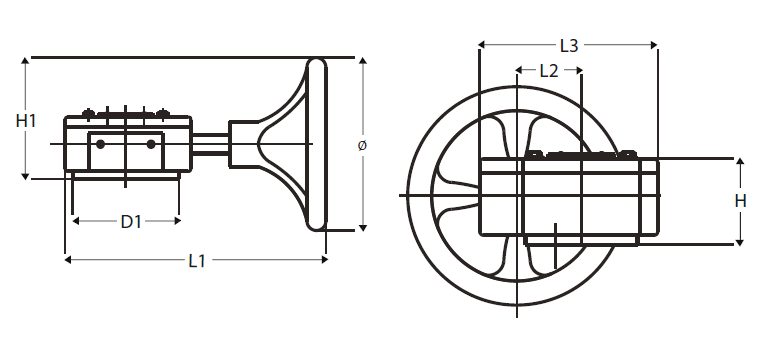

Cast Iron 1-Stage Worm Gear and Hand Wheel Carbon Steel Gear Box Shaft

| VALVE DIAMETER | D1 | ø | H | H1 | L1 | L2 | L3 |

| DN50 – DN150 | 108 | 145 | 65 | 113 | 212 | 45 | 129 |

| DN200 – DN250 | 146 | 285 | 70 | 182 | 305 | 62 | 171 |

| DN300 – DN350 | 165 | 285 | 77 | 182 | 300 | 85 | 198 |

| DN400 – DN 450 | 234 | 385 | 103 | 247 | 423 | 120 | 280 |

| DN500 – DN600 | 276 | 385 | 143 | 270 | 490 | 122 | 316 |

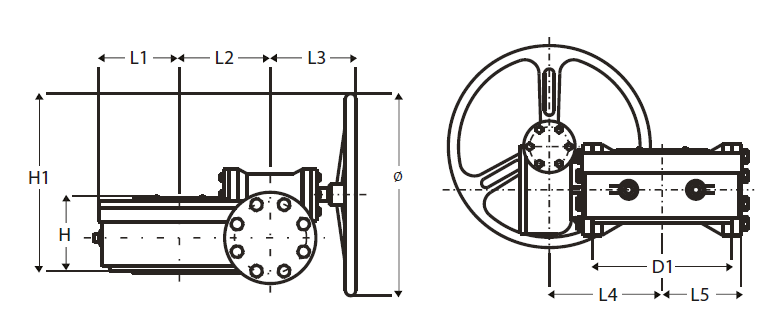

Cast Iron 2-Stage Worm Gear and Hand Wheel Carbon Steel Gear Box Shaft

| VALVE DIAMETER | D1 | ø | H | H1 | L1 | L2 | L3 | L4 | L5 |

| DN400 – DN450 | 197 | 285 | 125 | 271 | 107 | 100 | 156 | 168 | 107 |

| DN500 | 197 | 285 | 124 | 276 | 107 | 100 | 160 | 175 | 107 |

| DN600 | 276 | 385 | 136 | 330 | 131 | 125 | 160 | 193 | 131 |

| DN700 – DN 750 | 300 | 425 | 158 | 373 | 173 | 162 | 197 | 244.5 | 173 |

| DN800 – DN900 | 300 | 425 | 149 | 378 | 146 | 140 | 197 | 230 | 146 |

| DN1000 – DN1100 | 300 | 425 | 185 | 409 | 201 | 196 | 203 | 279 | 201 |

| DN1200 | 350 | 425 | 216 | 423 | 185 | 240 | 203 | 311 | 255 |

| DN1400 | 415 | 510 | 267 | 553 | 208 | 345 | 258 | 435 | 355 |

| DN1600 | 470 | 510 | 312 | 562 | 316 | 410 | 237 | 450 | 425 |

| DN1800 | 560 | 510 | 326 | 570 | 360 | 460 | 237 | 466 | 475 |

| DN2000 | 650 | 600 | 48 | 240 | 410 | 602 | 265 | 725 | 630 |

| DN2200 – DN2400 | 800 | 600 | 570 | 240 | 442 | 696 | 364 | 742 | 726 |

| DN2600 – DN3000 | 800 | 600 | 520 | 240 | 438 | 768 | 364 | 742 | 726 |

INSTALLATION & OPERATION GUIDE

- Ensure sufficient space for valves for easy installation, operation, maintenance and replacement.

- Verify the valves are suitable for the operating condition such as medium, operating pressure / temperature, etc.

- Check the I.D. of the flange and pipe to ensure free disc movement.

- Valves shall be mounted on flanges only after the counter flanges have been welded to pipe and cooled down to the atmospheric

temperature. Welding heat may damage the rubber seat of the valves. Never weld the flanges with valves installed. No gasket is

required for installation of rubber seated butterfly valves. - Position the valves carefully between flanges. Accurate centering between flanges is essential to prevent any damages and

problems during operation. - Valves should be installed by placing bolts through the hole and tightening carefully, ensuring even contact between the flange

and seat. Too tight of space may cause damages to the seat and should be avoided. - Cross tighten all the bolts diagonally to distribute the loads evenly over the valves.

- Turning the valves to ensure sufficient disc clearance.

- Valves equipped with manual operators must be operated manually. Excessive external force on the operation of valve may

damage the valve and / or operator.